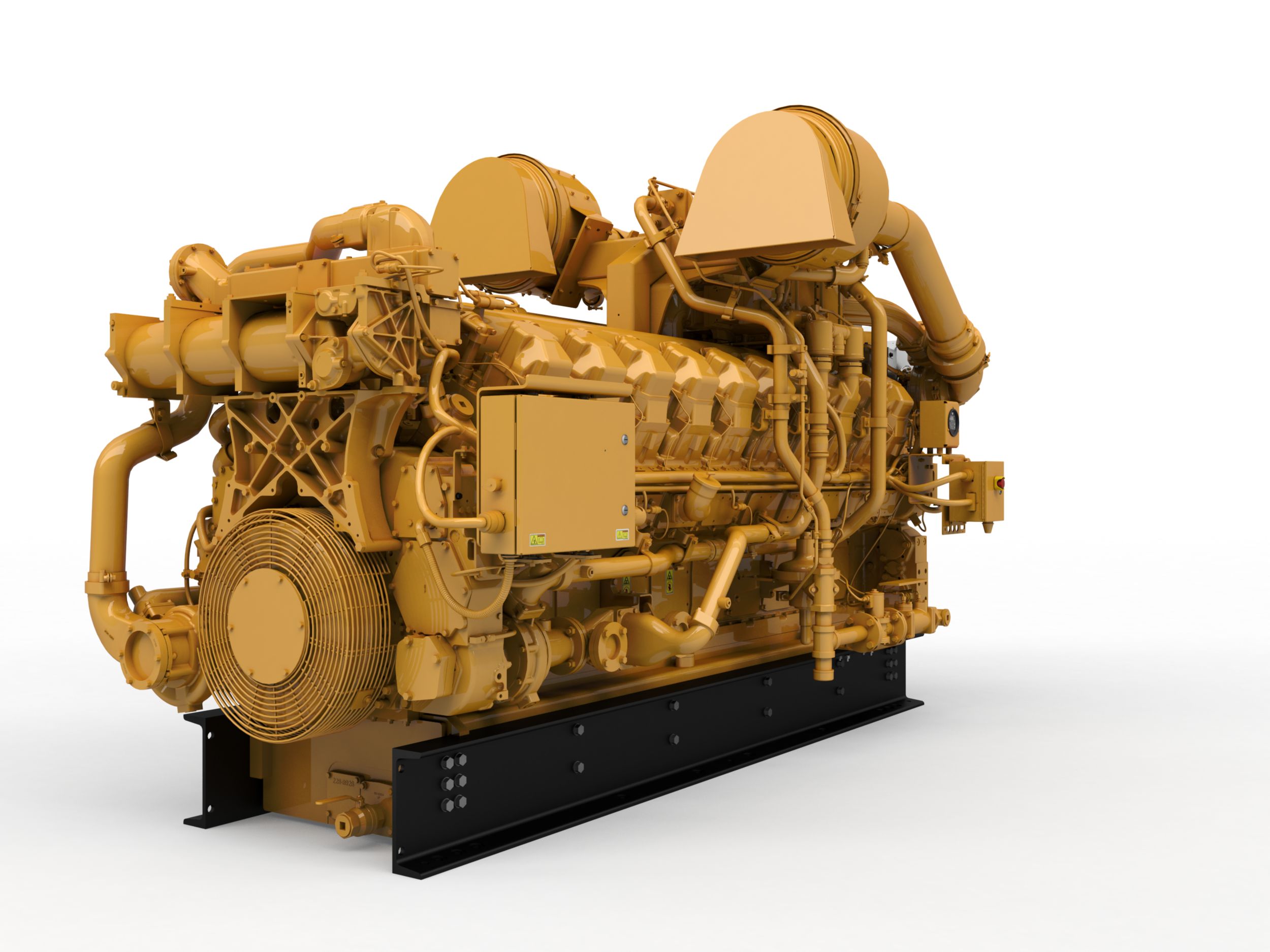

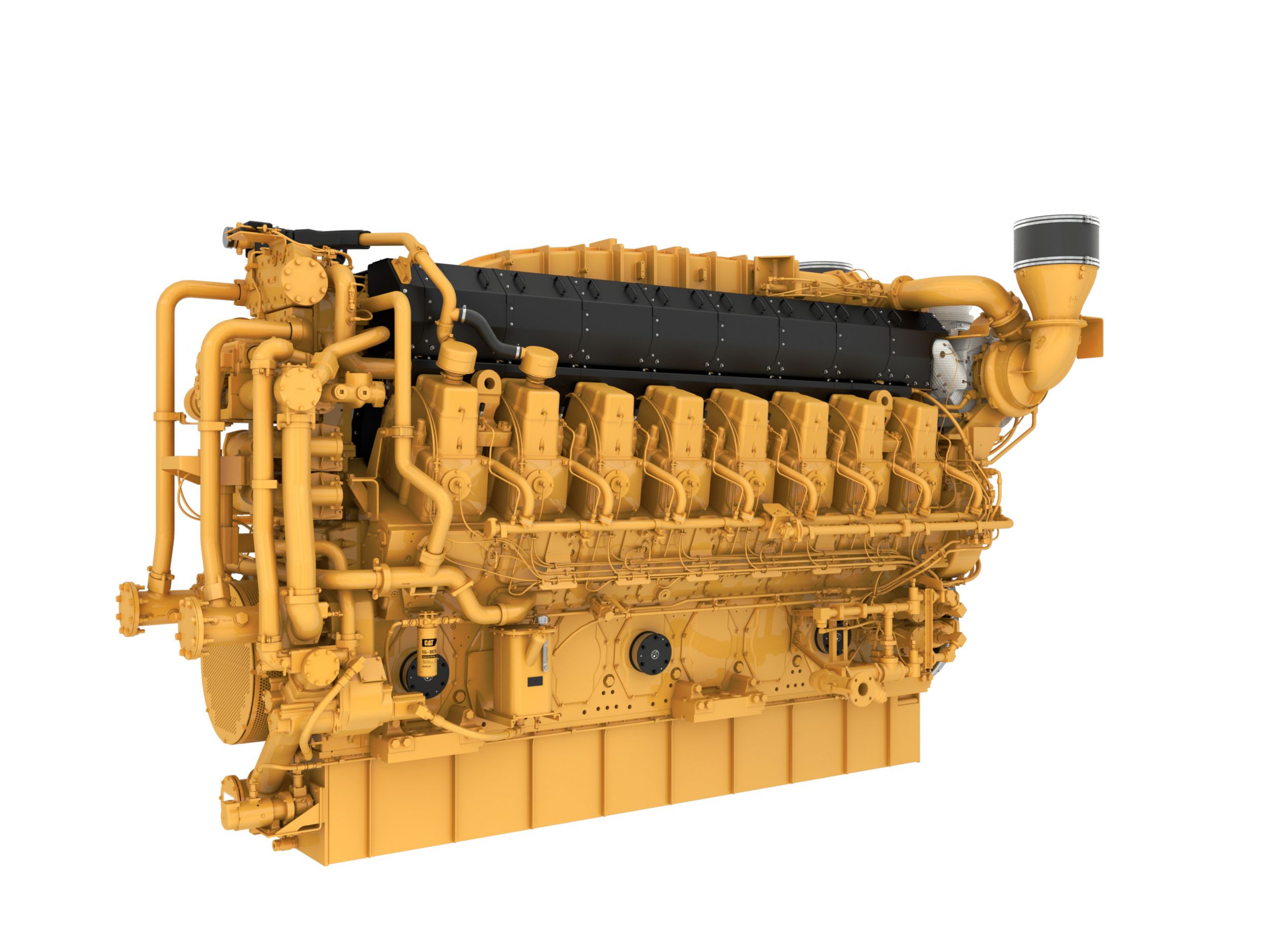

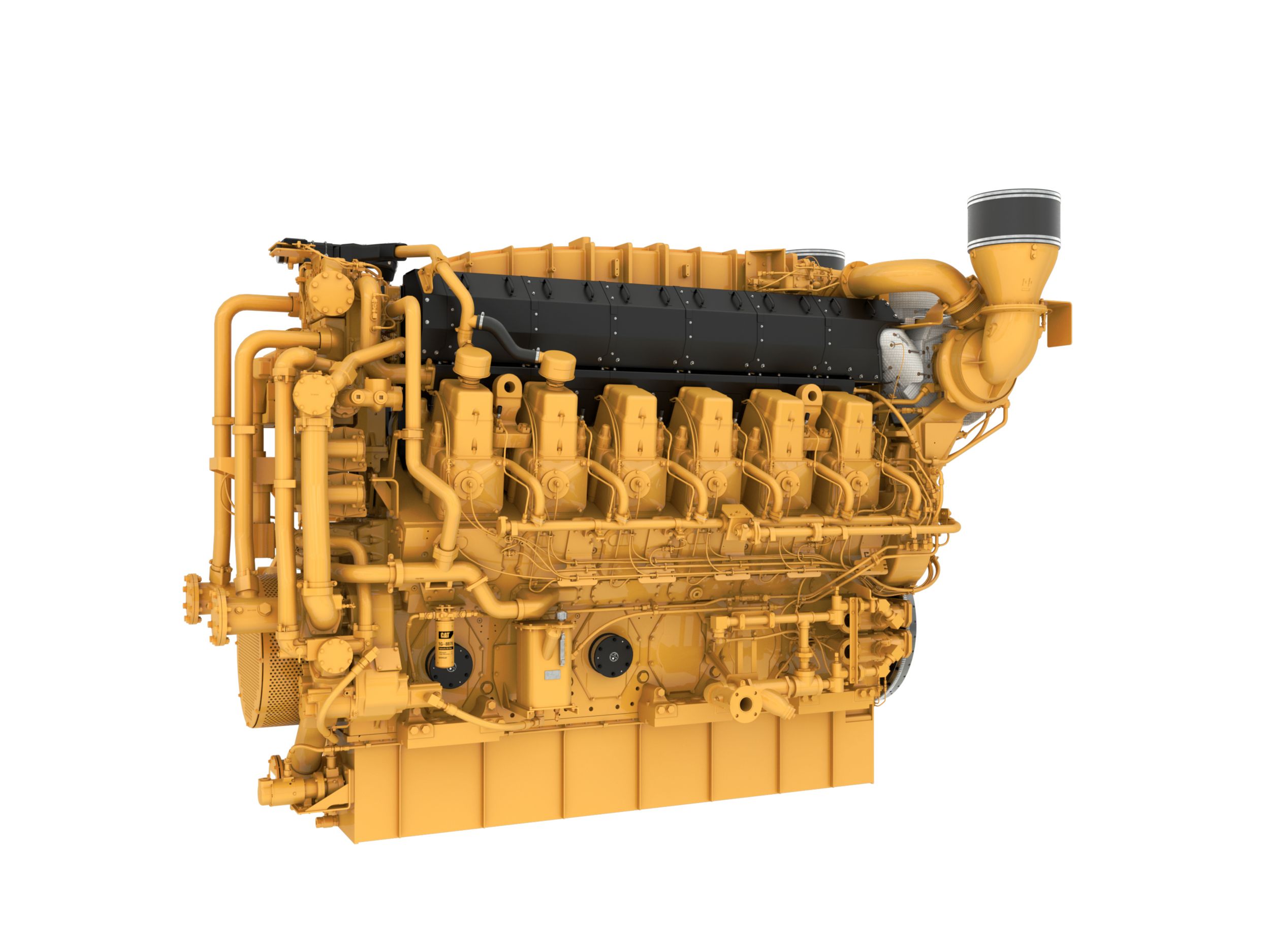

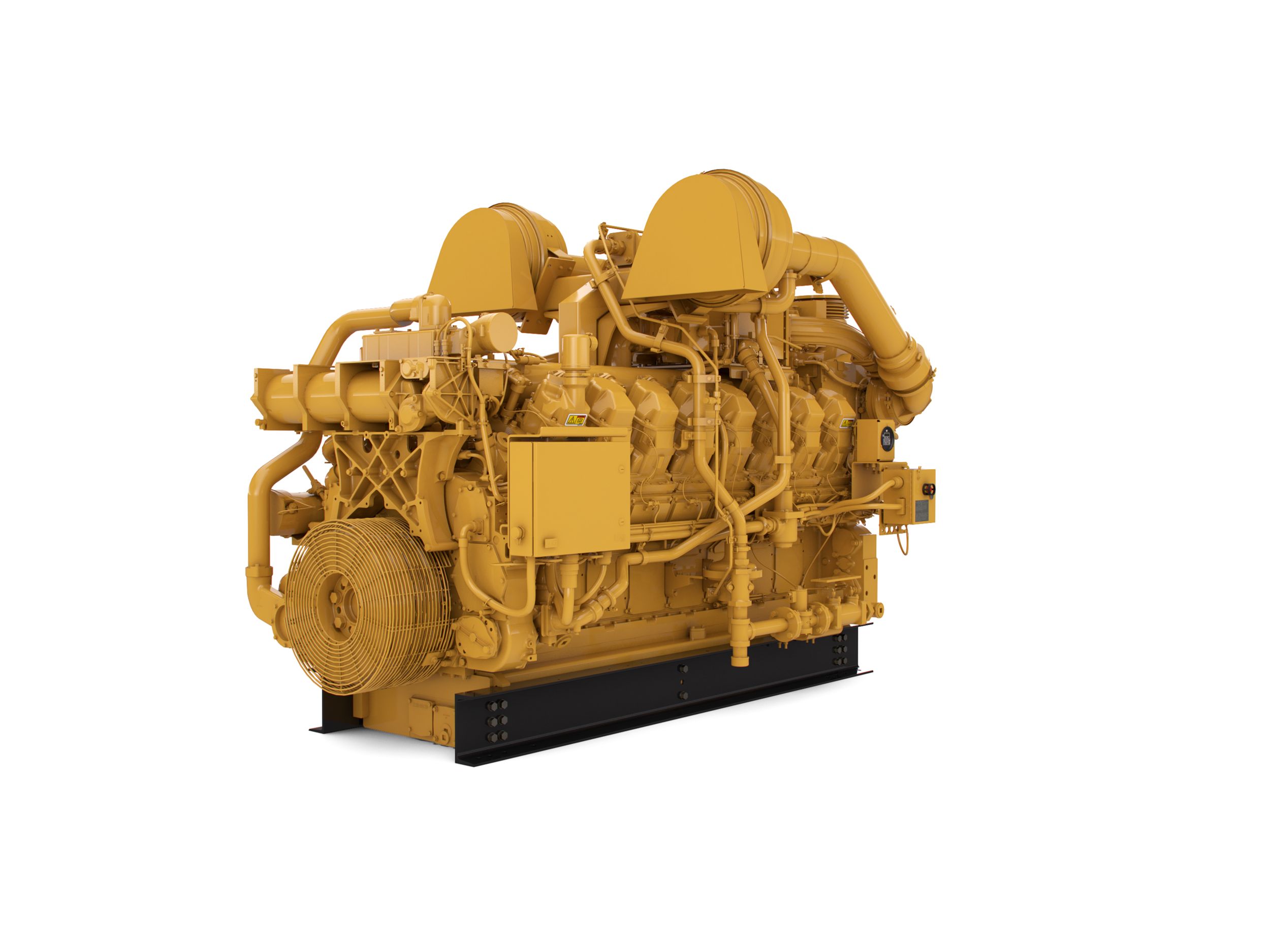

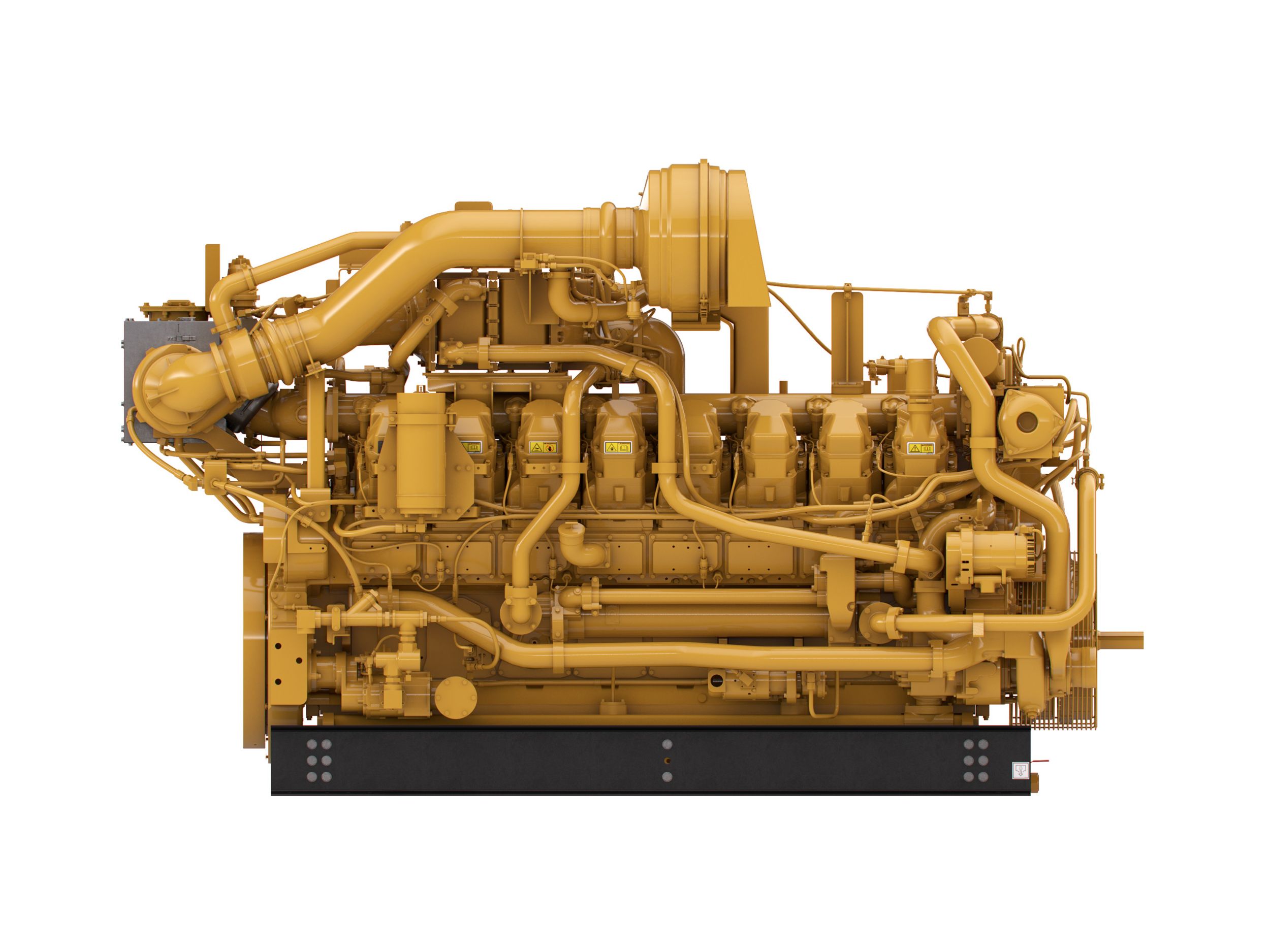

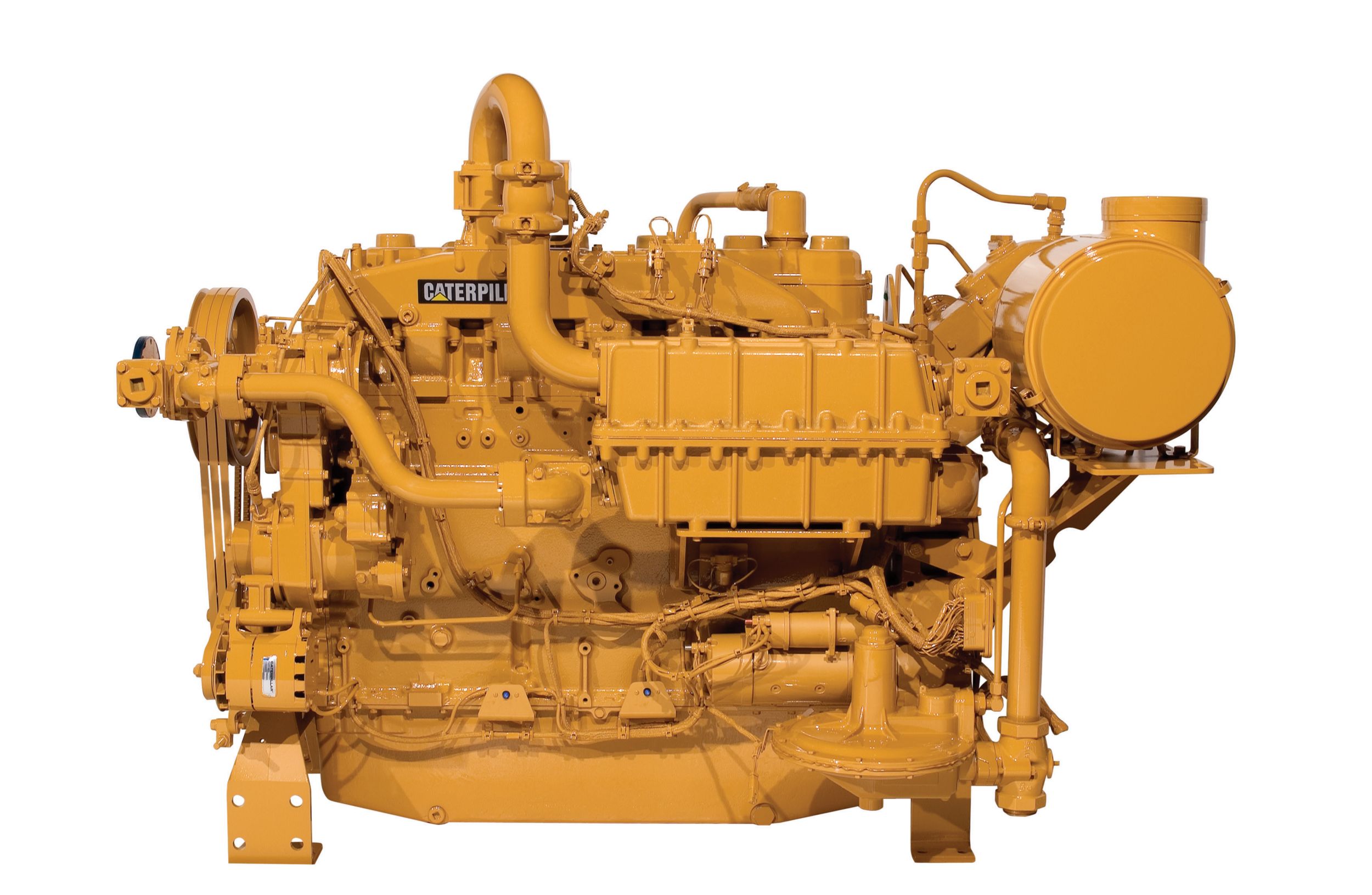

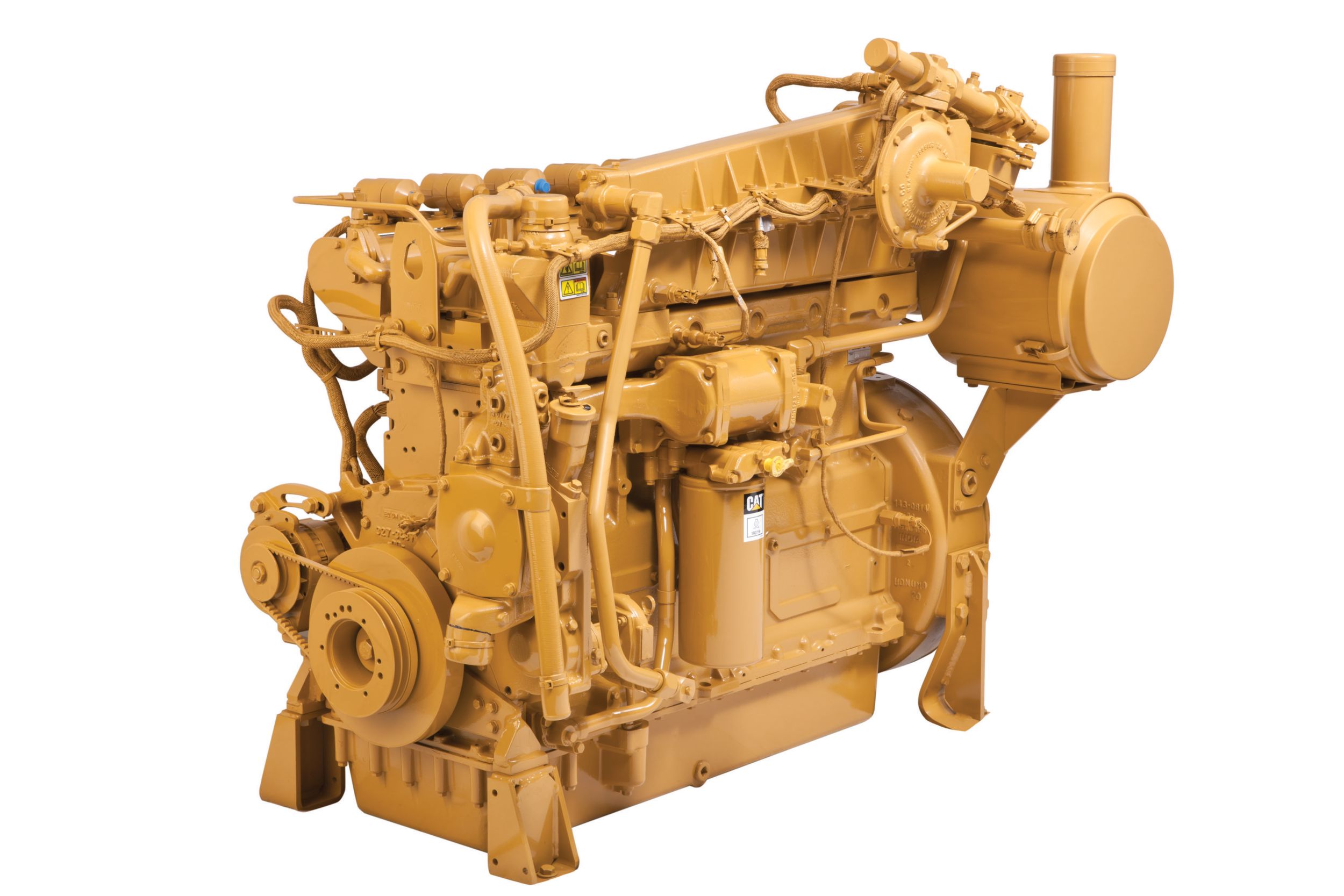

G3520J Gas Compression Engine

Gas Compression Engines

Details

Emissions

U.S. EPA Spark Ignited Stationary NSPS emissions for 2010

Minimum Rating

1725.0 BHP

Bore

6.7 in

Overview

The line of G3520J engines brings versatility, uptime, and low operating cost to your gas compression operation. They deliver the lowest engine-out emissions in the industry without sacrificing performance. Ideal applications for G3520J engines include primary gathering, central gathering, and gas processing plants.

Features at a Glance

- Engine Design

-

- Built on G3500 LE proven reliability and durability

- Ability to burn a wide spectrum of gaseous fuels

- Robust diesel strength design prolongs life and lowers owning and sdfsoperating costs

- Broad operating speed range at lower site air density (high altitude/ sdfshot ambient temperatures)

- Higher power density improves fleet management

- Quality engine diagnostics

- Detonation-sensitive timing control for individual cylinderst temperatures)

- Ultra Lean Burn Technology (ULB)

-

ULB technology uses an advanced control system, a better turbo sdfamatch, improved air and fuel mixing, and a more sophisticated sdfscombustion recipe to provide:

- Lowest engine-out emissions

- Highest fuel efficiency

- Improved altitude and speed turndown

- Stable load acceptance and load rejection

- Emissions

-

- Meets U.S. EPA Spark Ignited Stationary NSPS emissions for 2010 and some non-attainment areas

- Lean air/fuel mixture provides best available emissions and fuel efficiency for engines of this bore size

- Advanced Digital Engine Management

-

ADEM A3 engine management system integrates speed control, air/fuel ratio control, and ignition/detonation controls into a complete engine management system. ADEM A3 has improved: user interface, display system, shutdown controls, and system diagnostics.

- Full Range of Attachments

-

Large variety of factory-installed engine attachments reduces packaging time

- Testing

-

Every engine is full-load tested to ensure proper engine performance

- Gas Engine Rating Pro

-

GERP is a web-based program designed to provide site performance capabilities for Cat® natural gas engines for the gas compression industry. GERP provides engine data for your site’s altitude, ambient temperature, fuel, engine coolant heat rejection, performance data, installation drawings, spec sheets, and pump curves.

- Product Support Offered Through Global Cat Dealer

-

- More than 2,200 dealer outlets

- Cat factory-trained dealer technicians service every aspect of your petroleum engine

- Cat parts and labor warranty

- Preventive maintenance agreements available for repair sdfsbefore-failure options

- S•O•SSM program matches your oil and coolant samples sdfdagainst Caterpillar set standards to determine:-Internal engine component condition-Presence of unwanted fluid-Presence of combustion by-products-Site-specific oil change interval

- Web Site

-

For all your Oil & Gas power requirements, visit www.cat.com/oilandgas

Specifications

Full Specifications

- Engine Specifications

-

Emissions

U.S. EPA Spark Ignited Stationary NSPS emissions for 2010Minimum Rating

1725.0 BHPBore

6.7 inRotation from Flywheel End

CounterclockwiseStroke

7.5 inCombustion

Lean BurnOil Change Interval

2000 hrs

- Capacity for Liquids

-

Lube Oil System - Refill

143 gal (US)

- Governor and Protection

-

Governor and Protection

Electronic (ADEM™ A3)

Equipment

- Standard Equipment

-

Air Inlet System

- Axial Flow Air cleaner

- Single element canister type with service indicator

Cooling System

- Two-stage charge air cooling: First stage - JW + OC + 1st stage AC / Second stage - 2nd stage AC

- Jacket water and aftercooler thermostats

Exhaust System

- Water-cooled exhaust manifolds

- Dry turbocharger housings

- Water-cooled exhaust elbow

Flywheels and Flywheel Housings

- SAE No. 21 flywheel

- SAE No. 00 flywheel housing

- SAE standard rotation

Fuel System

- 7-40 psig gas supply

- Electronic fuel metering valve

- Gas pressure regulator

- Gas shutoff valve

Instrumentation

- Remote-mounted Advisor control panel

- Product Link cellular radio

Lubrication System

- Crankcase breather — top mounted

- Oil cooler

- Oil filter — RH

- Oil pan — 143 gal

- Oil sampling valve

- Turbo oil accumulator

Mounting System

- Rails

Power Take-Offs

- Front housing — two-sided

- Front lower LH accessory drive

General

- Paint — Cat yellow

- Crankshaft vibration damper and guard

- Optional Equipment

-

Air Inlet System

- Round air inlet adaptors

- Rain shield

Charging System

- CSA alternator (24V,65A)

Cooling System

- Jacket water inlet flange-hose connection

Exhaust System

- Flexible fittings

- Flanges

- Elbow

Fuel System

- Fuel filter

Instrumentation

- LAN adapter

- 15',40',90',140' Product Link extension harness

- 20',30',50',100' interconnect harness

Lubrication System

- Lubricating oil

- Oil bypass filter

- Air prelube pump

- Oil pan drain

Power Take-Offs

- Front stub shaft

- Crankshaft pulley

Starting System

- Air pressure regulator

- 90 psi starter

- 150 psi starter

- Jacket water heater

General

- Special paint

- Crankshaft vibration double damper

- Explosion relief valves

EU Certification

- EEC DOI certification